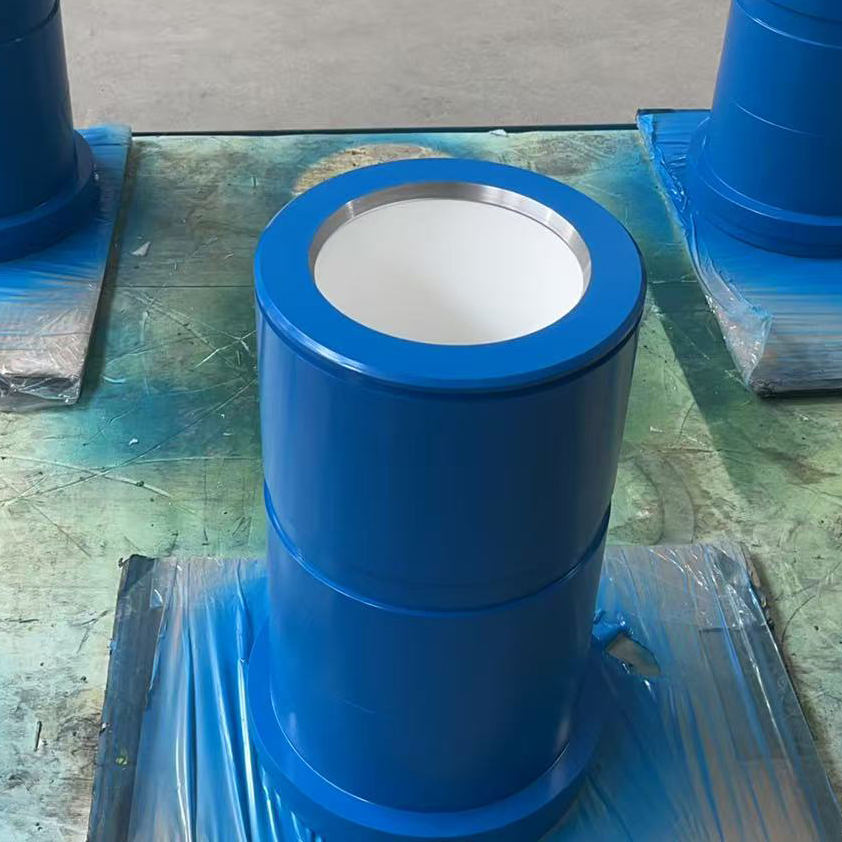

Ceramic-Zirconia Liners

1.More corrosion resistance, high temperature resistance, high pressure resistance

2. Labor cost and maintenance cost are greatly reduced

3. Longer service life

Wechat consulting

Details

Product introduction

1.High strength forged steel outer hull.

2.Zirconia inner sleeve.

3.Significant longer service and lifetime cost saving.

4.Better resistance to heat and corrosion.

5.Smoothness of Zirconia inner bore translates into longer service lifetime for pistons.

peculiarity

1.More corrosion resistance, high temperature resistance, high pressure resistance

2. Labor cost and maintenance cost are greatly reduced

3. Longer service life and lower overall cost than other cylinder liners

Product Description

Ceramic Cylinder Liner is a high-performance product developed by phase change toughening technology.

It has a number of significant advantages:

Excellent wear resistance: It can effectively resist wear and extend its service life during use.

Excellent corrosion resistance: Stable performance even in harsh chemical environments.

Good high pressure resistance: can withstand high pressure, suitable for a variety of complex drilling environment.

Excellent high temperature resistance: it can still work normally under high temperature conditions to meet the needs of different operating scenarios.

High strength and hardness: ensure the structural stability and reliability of the cylinder liner.

Ceramic Cylinder Liner has good performance and long service life, which is especially suitable for drilling environment with deep oil reservoir and harsh geological structure, as well as offshore oil and gas development operations. Under these demanding working conditions, it can operate stably and has a service life of more than 4000 hours.

This high-performance Ceramic Cylinder Liner is particularly suitable for the following environments:

Drilling environments with deep oil reservoirs and harsh geological structures: In these environments, drilling equipment is subjected to extreme operating conditions such as high temperature, high pressure and corrosion. Ceramic liner's resistance to wear, corrosion and high pressure makes it an ideal choice.

Offshore oil and gas development operations: In offshore environments where equipment is exposed to salt spray corrosion and other harsh conditions, the corrosion resistance and high temperature resistance of zirconia ceramic liner can effectively extend the service life of equipment.

Product Pictures

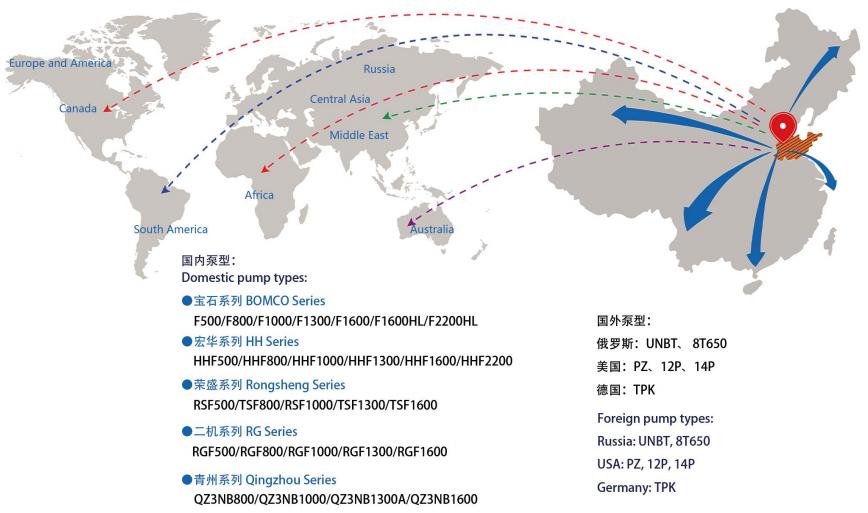

Available production models

Bomco:

F-500、F-800、 F-1000、 F-1300、 F-1600、F-1600HL、F2200HL

Hong Hua:

HHF-500、 HHF-800、 HHF-1000、HHF-1300, HHF-1600、HHF2200HL、3NB1300F

IDECO:

T-500、T-800、 T-1000、 T-1300、 T-1600、MM-450、MM-500-F、MM-600-A、MM-700-F、MM-1000

LS-National Mud Pumps:

3NB-500C、3NB-1000C、3NB-1300C、 3NB-1600

National:

7-P-50、 8-P-80、 9-P-100、 10-P-130、12-P-160、14-P-220、JWS-165-L、JWS-340 JWS-400 C-250 C-350 K-380 K-500-A G-700 K-700 N-1000 N-1300 N-1600

Oilwell:

350-PT、 A-650-PT、A-850PT、 A-1100-PT、 A-1400-PT、 A-1700-PT、HD-1400-PT、HD-1700-PT、612-P、212-P、214-P、218-P、700-P、816-P、818-P、1000-P

Soilmec:

7T500、 7T508、 8T650

TSC:

WF-400、 WF-450、 WF-700、 WF-1000、 WF-1300、 WF-1600、WF-2000

Weatherford:

MP-5、MP-8、 MP-10、 MP-13、 MP-16

Wirth:

TPK-1000、TPK-1300 、TPK-1600、TPK-2000 、TPK-2200

Russian Pumps:

UNBT-950、UNB-600、8T650、UNBT650、NBT600、UNBT1180、UNBT1180L

Upetro:

3PN-1000 3PN-1600 3PN-1300 3PN-2000

OPI:

350-D,350-GD,500-DC,700-HDL,1000HDL

TFI:

BH-800 F-500 -F800 F-1000 F-1300 F-1600

Lexco/Ewco:

W-250-C WH440 W446 W600 WH600 WH770 W1100 WH1312 W1612 W1712 W2000 W2214 W2215

Loadmaster:

LSF-500 LSF-800 LSF-1000 LSF-1300 LSF-1600

Soilmec:

7T500 7T508 8T650

Dragon:

440HP 660HP

Graet American:

GA-550 GA-750

American Block:

K-800、K1000、K1300、K1600、K2200

Brewster:

B-1000-T、 B-1100-T、 B-1300-T、 B-1600-T

Drillmec:

7TS600、8T800、9T800、9T1000、10T1300、12T1600、14T-2200、8D1S

Ellis Williams (Lewco):

E447、E2200、W446、W440、Etc

Gardner Denver:

PZ-7、PZ-8、 PZ-9、 PZ-10、 PZ-11、PAH275

All conventional pump type accessories can be produced

Related product display

Factory environment

Production equipment