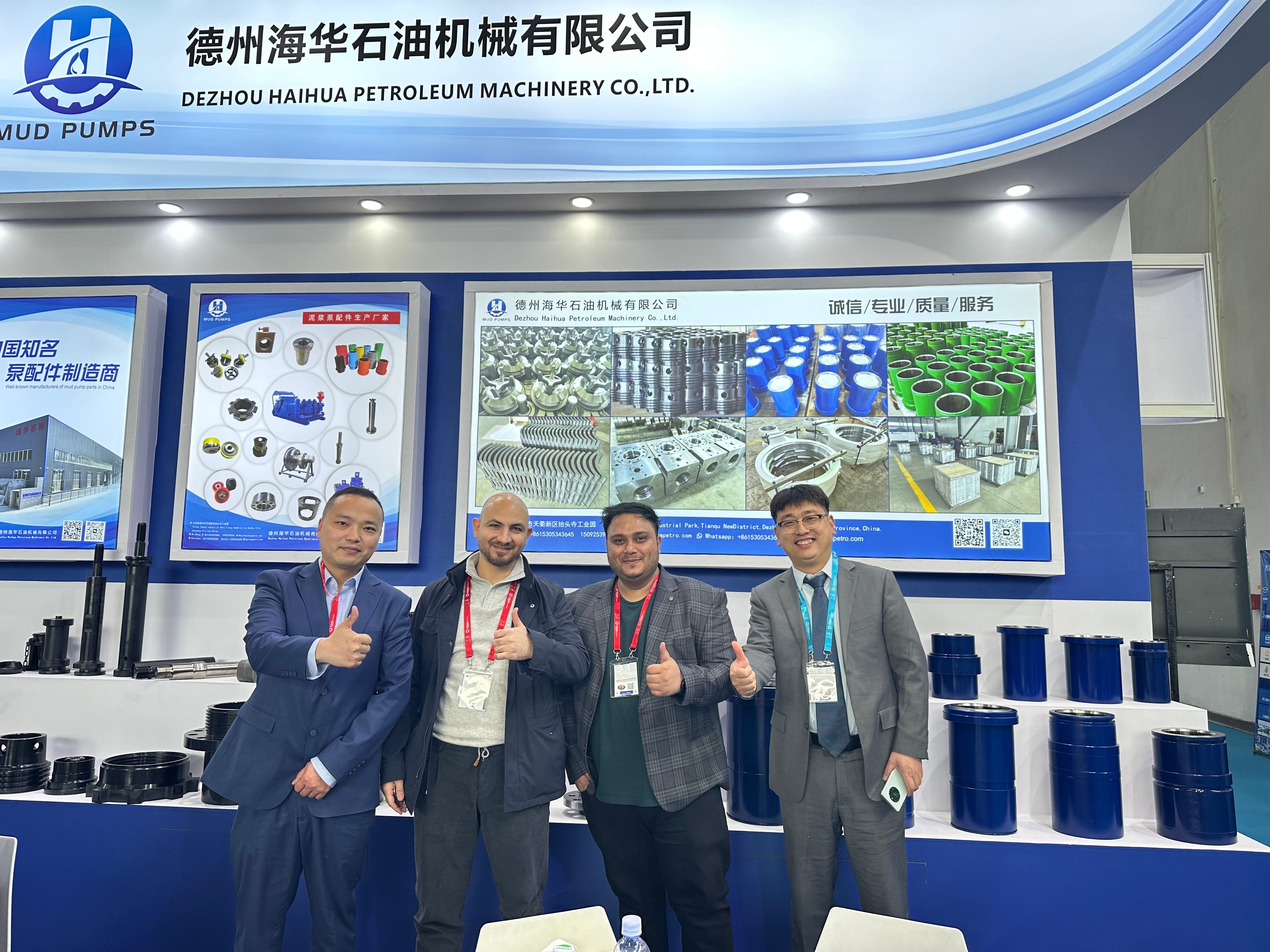

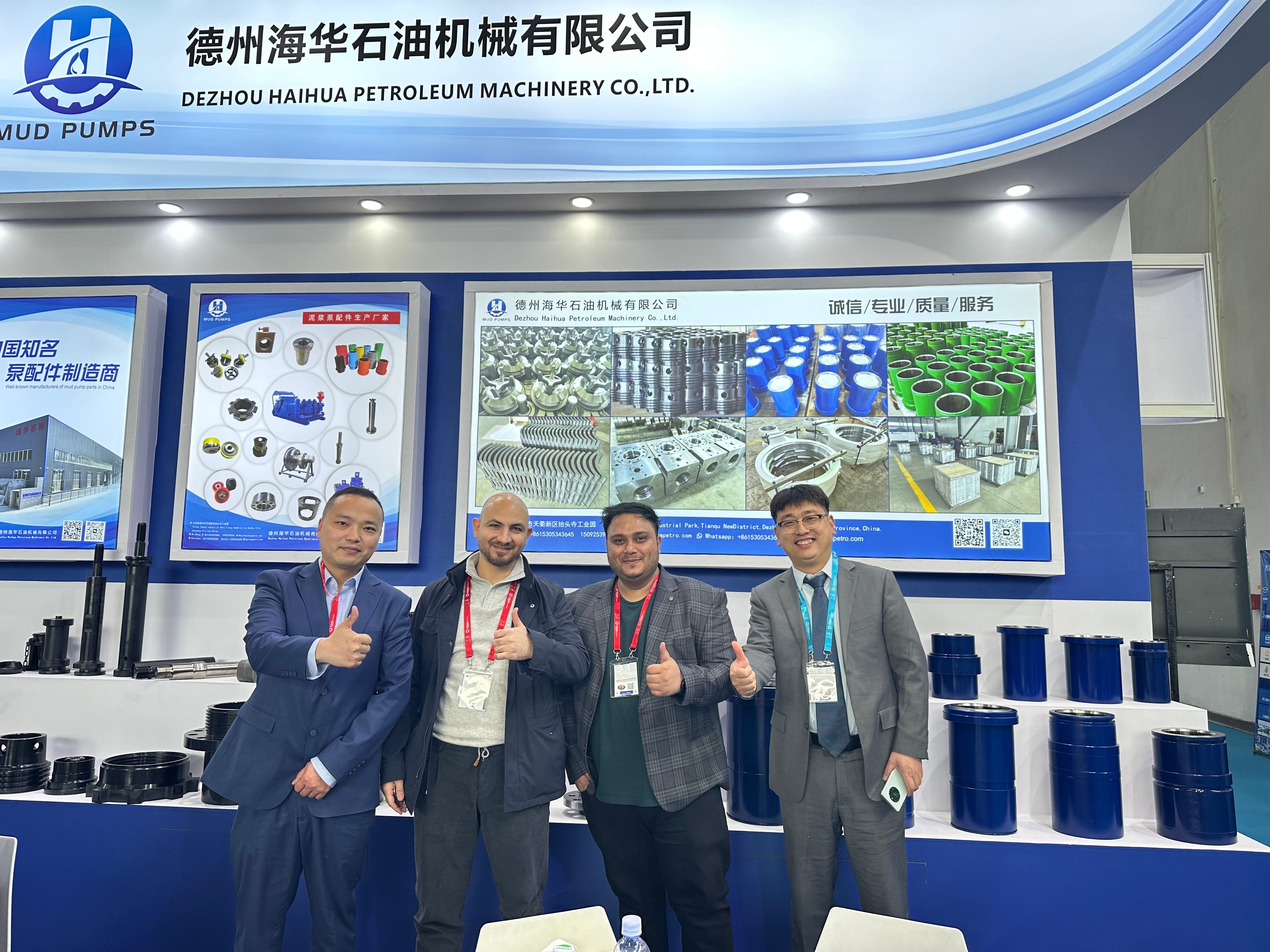

We’re crushing the 2025 Beijing Exhibition! 🚀

Dezhou Haihua Petroleum Machinery—your go-to source factory for mud pump spare parts—is here with our full product line: liners, pistons, and all precision components.

Our “reliability” isn’t just a slogan—it’s what earned us the double thumbs-up from international clients on-site.

If you’re in the oil equipment circle, swing by our booth to check out the goods (and chat with the team)!